Particulate emissions from cement kilns have been reduced significantly over the last few decades due in part to ever-tightening regulatory controls including the lowering of emission limit values (ELVs) and the associated increase in installations of highly effective filtration systems which require higher quality monitoring.

- Main emissions to air are from the kiln system

- Additional potential sources include crushing plant, coal mills, clinker mills and silos

Recognising differing environmental conditions and process applications require different particulate emission measurement technology options, ENVEA offers an extensive technology range including Light Scatter, Probe Electrification, Opacity and Ratiometric Opacity for regulatory compliance and to facilitate filter and process optimisation.

- Stack particulate emissions compliance measurement

- Baghouse chamber and filter performance monitoring

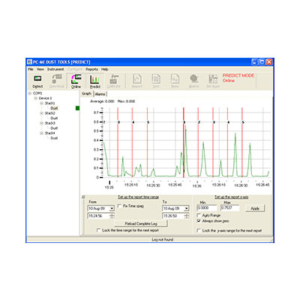

- Predictive bag filter row monitoring

PM CEMS IN THE KILN STACK: TECHNOLOGY CONSIDERATIONS

MONITORING BEYOND THE MAIN KILN STACK

Bag filter arrestment plants can be monitored by a networked system of ElectroDynamic™ Probe Electrification instruments, certified to TUV and MCERTS performance standards with patented features to a high performance under a wide range of process conditions