Total mercury emissions monitor in stack flue gases

Beneficiary of over 20 years of experience in mercury measurement, the new SM-5 CEMS Hg analyzer is designed to provide extremely accurate and reliable continuous measurements of very low concentrations of Hg in flue gas emissions.

The SM-5 features short response times, dynamic ranges and stable measurement under all circumstances.

QAL1 certification range 0-5 µg/m3, the lowest on the market

- Features & Benefits

- Main applications

- Technical Specifications

- User benefits

- Approvals & Certifications

- Downloads

- Certification ranges: 0-5 : 0-30; 0-45; 0-100; 0-1000 µg/m3

- Very high accuracy: <0,1 μg/m3 over 3 months

- Dynamic range switching for reliable measurement of mercury emission peaks

- Photometric measurement independent of the high-temperature converter to ensure very low maintenance times and costs

- High temperature conversion method: requires no reagent, water refill or cartridge replacement

- Does not require a calibrator to operate: reliability & reduced operating costs

- Modular mercury injection system at the probe or at the analyzer for complete AMS checks

- Probe head port for optionally connecting a calibration system

- No need for carrier gas, dilution or air conditioning, very low utilities consumption (no nitrogen required)

-

li>Sampling box mounted on the stack: no maintenance required, no transport of reactive Hg

- Two different power sources (protected/unprotected) in order to separate and secure the measuring system

- Automatic backflush function

- Low maintenance and optimized operating costs

- Option: Performance Control System.

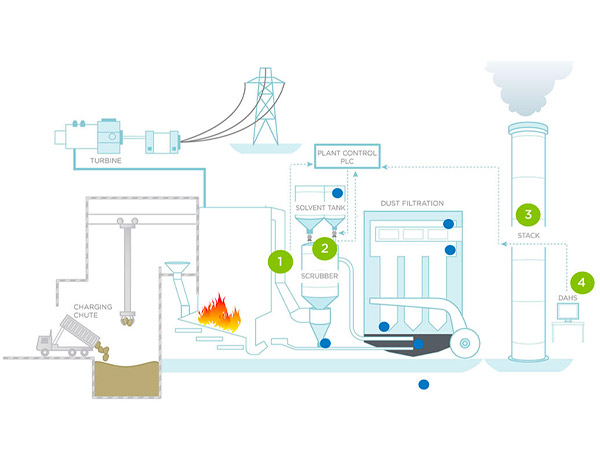

- Hg CEMS monitor perfectly adapted for continuous mercury analysis in:

- Waste Incineration plants (industrial, medical, hazardous waste, sewage sludge…)

- Coal-fired power plants (before and after mercury absorbers)

- Cement kilns

- Determination of mercury at sulphur acid production plants

- Thermal treatment of contaminated soils, hazardous waste

- Metallurgical facilities with potential Hg emissions…

| Technical Specifications | |

|---|---|

| QAL1 certification range | 0-5 µg/m3 Additional ranges: 0-30; 0-45; 0-100; 0-1000 µg/m3 |

| Detection limit | < 0.05 µg/m3 (system) |

| Precision (accuracy) | < 0.01 µg/m3 / 3 months |

| Max. drift | < 0.15 µg/m3 / 3 months |

| Operating temperature | +5°C to +40°C (without air conditioning) |

| Sample max temperature | 200°C as standard (others as option) |

| Display | Touch screen |

| Heated sampling line | custom-made: from 2 to 60 m |

| Communication | 4-20 mA, RS232, Modbus RTU/RS485, Modbus TCP/IP, TCP-IP |

| Power supply | 230 V / 50 Hz or 110 V / 60Hz |

| Power consumption | Analyzer cabinet: 1850W (total) Sampling box: 800W Probe controller: 600W (0,6m), 800W (1m) or 1200W (1,5m) Heated line: 120W/m |

| Air instrument consumption | 5-10 bar, max. 16 L/min (for backflush) |

| Mounting flange | DN65 / PN6, other on request |

| Dimensions (H x L x W) cm | Analyzer cabinet: 190.5x80x65 Sampling box: 26x34x34,5 Probe controller: 25x35x15 (27x38x18 incl. fixations) |

| Weight | Analyzer cabinet: 224 kg Sampling box: 15.4 kg Stinger: 9 to 12 kg, depending on length Probe controller: 10 kg |

| Protection Rating | Analyzer cabinet IP55, Sampling IP54, Probe controller IP66 |

| FEATURES | BENEFITS |

|---|---|

| Very low certification range | High measurement accuracy |

| Instrument certified to operate without calibration | Reliability & reduced operating costs |

| Simple and robust design | Maximum availability, easy servicing with low maintenance costs |

| Converter oven without catalyst | Requires no consumables, minimized operating costs |

| Very low instrument air consumption | Lower operating costs |

| Customizable heated sampling line | Remote installation for easy access to the analysis cabinet |

| Over 20 years of expertise in mercury analysis | Guarantee of a high quality and high performance product |

- QAL1 certification by the TÜV Rheinland Energie und Umwelt GmbH laboratory, according to EN 14181, EN 15267-1, EN 15267-2, EN 15267-3 (European regulation);

Download the TÜV certificate: 0000074628

- MCERTS certified for stack emissions monitoring equipment at industrial installations – Continuous emissions monitoring systems(CEMS) to EN 15267-1:2009, EN15267-2:2009, EN 15267-3:2007 & QAL 1 as defined in EN 14181: 2014

Download the MCERTS certificate CSA MC220404/00

- New Waste Incineration BREF

- Industrial Emissions Directive (IED) 2010/75/EU

- Large Combustion Plant Directive (LCPD) BREF

- Integrated Pollution Prevention Control (IPPC) Directive

- Meets national and international regulatory requirements

- Performance Specification 12A for Mercury | US EPA 40 CFR Parts 60 and 63

- National Emission Standards for Hazardous Air Pollutants (NESHAP) for the Portland Cement Manufacturing Industry

- Minamata convention & European directives for thermal power plants, waste incinerators and large combustion plants

Our mercury analyzers are manufactured according to the ISO 9001 quality regulations.

CE approved