- Features & Benefits

- Main applications

- Technical Specifications

- Technical Data

- Mounting Installation

- Downloads

- Detects all dust types

- Relay alarm output

- Usable in clean gas and any metallic dust channels

- Very simple and fast retrofitting

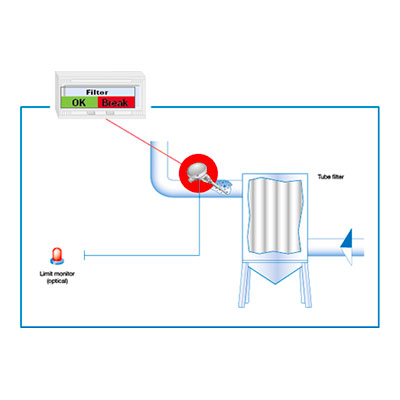

- Immediate detection of filter damages

- Simple commissioning (Plug & Play)

- Excellent price / performance ratio

- Easily expandable to 4 … 20 mA output (trend signal) with optional DRC

- Aluminium

- Cement

- Chemistry

- Electronics

- Extraction

- Fertilizer

- Food

- Glass

- Granite

- Mills

- Products of carbon

- Quartz sand

- Wood

- Metal

- Building materials

- Power plant

- Surface purification

- Automotive

- Can be used in metal channels

- Operational range: starts at dust volumes of 0.1 mg/m3

| Sensor Technical Data | |

|---|---|

| Measurement objects | Solid particles in a gas flow |

| Measurement range | From 0.1 mg/m3 |

| Process temperature | Max. 140 °C (higher temperature on request) |

| Ambient temperature | – 20 . . . + 60 °C |

| Pressure | Max. 2 bar |

| Gas velocity | Min. 4 m/s |

| Humidity | 95 % RH (non-condensing) |

| Principle | Electrodynamic technology |

| Damping time | 1 s |

| Output signals | 1 Alarm output, potential-free, NO/NC |

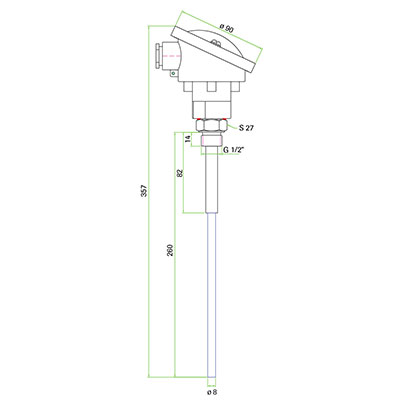

| Sensor rod | Total length: 260 mm, length of stainless steel rod: approx. 194 mm |

| Enclosure | Aluminium |

| Using in Ex-zones | Cat. 3 G/D (zone 2 gas / zone 22 dust) |

| Protection category | IP65 |

| Power supply | 24 ± 10 % V DC |

| Power consumption | 1 W |

| Electrical connection | • screw-type / terminal box • M12 connector (optional) |

| Assembly | Via ½“ thread or Tri-Clamp connection |

| Weight | Approx. 0.7 kg |

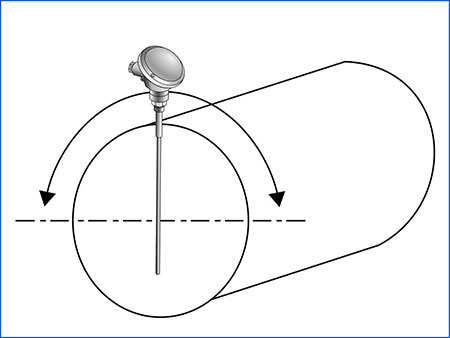

| Determination of the installation location: The best installation height for the sensor in a channel or a pipeline is located in an area in which the particles are subject to an even distribution and with constant speed. In an ideal case, the channel or pipeline will run horizontally or vertically, and installations such as curves, flaps or sliders should have a minimum distance of 5 times the pipeline diameter in every flow direction to the sensor rod . The Dusty has to be installed in a metal channel to achieve sufficient shielding against electric influences from the outside and good earthing. For non-metallic lines, a sheath made of metal, or in the form of a metal foil or a fine-mesh metal net with a length of approx. 5 times the pipe diameter around the measurement area of the line must be installed.

Installation of the sensor: |

|