Continuous material flow detection (Flow / NoFlow)

Microwave sensor for contactless monitoring of material flow and detection of material blockage

The system operates with no contact in a process in which the material movement is detected by using the Doppler effect.

The FlowJam is a process-secure device, since the microwave technology used can penetrate material coating on the sensor and reliably detect the material movement behind it. If container walls, housings or pipelines are not metal, it is possible to measure from the outside.

- Features & Benefits

- Main applications

- Technical Specifications

- Technical Data

- Mounting Installation

- Downloads

- Absolutely insensitive against material deposits

- For any line diameter

- With adapter, usable up to 220 °C and 20 bar

- Compact (no separate electronics)

- With ceramic mounting, usable up to 1000 °C

- Signalling through relay switching

- Different sensitivity levels

- Detection through all non-conductive walls

- Can also be supplied with short housing and separate electronics

- Detection of material blockage and material standstill

- Steel

- Food

- Biomass

- Cement

- Chemistry

- Coal plant

- Coating

- Incineration

- Minerals

- Wood

- Lime plant

- Energy

- Gypsum

- Power plant

- Foundry

| Technical Specifications | |

|---|---|

| Material to detect | Dust, powders or granulates |

| Working principle | Microwave |

| Process pressure | Max. 20 bar |

| Process temperature | Up to +1000°C |

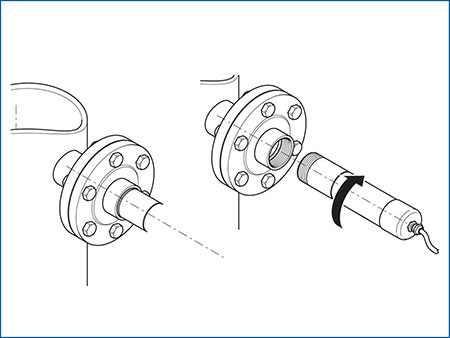

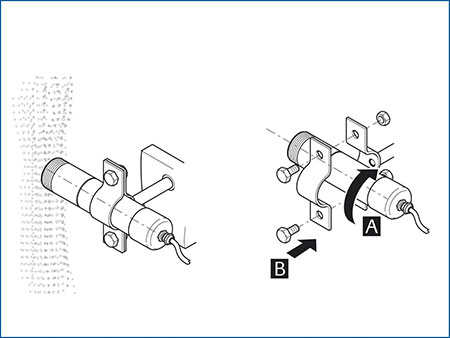

| Mounting | 1 1/2 ” threat connection |

| Type of Conveying | All |

| Flow rates | No limit |

| Pipe diameter/detection range | Up to 1200 mm |

| Output | Relay |

- For any line diameter

- With adapter usable up to 220 °C and 20 bar

- With ceramic mounting usable up to 1,000 °C

- Operates with no contact, using microwaves in a process in which the material movement is detected by using the Doppler effect

- Can also be used under difficult conditions such as high operating temperatures and pressures with the help of a process adapter

| Technical Data | |

|---|---|

| Housing material | Stainless steel 1.4571 |

| Protective system | IP 65 |

| Process temperature | -20…+80 °C -20…+220 °C (with process adapter) Max. 1000 °C (with ceramic flange) |

| Ambient temperature | -20…+60 °C |

| Working pressure | Max. 1 bar Max. 20 bar (with process adapter) |

| Power supply | 24 V DC/AC ± 10 % |

| Relay contact | Max. rated load: 250 V AC Max. peak current:6 A Max. rated load 230 V AC: 250 VA Max. breaking capacity DC1: 3/110/220 V: 3/0.35/0.2 A Min. switching load: 500 mW (10 V/5 mA) |

| Response time | 250 ms …15 s (continuously adjustable) |

| Measuring frequency | 24.125 GHz; ± 100 MHz |

| Transmitting power | Max. 5 mW |

| Weight | 1.0 kg |

| Dimensions | Housing: length of 216 mm / diameter of 52 mm Thread: length of 30 mm / diameter of G 1½” |

| Technical Data | ||||

|---|---|---|---|---|

| Pressure adapter | Temperature adapter | Food adapter | High temperature adapter | |

| Material | Stainless steel 1.4571, POM diaphragm |

Stainless steel 1.4571, Tecapeek diaphragm |

Stainless steel 1.4571, Tecapeek GF30 diaphragm |

Steel Ceramic diaphragm |

| Temperature | -20…+80 °C | Max. +220 °C | Max. +220 °C | Max. 1000 °C |

| Pressure | Max. 20 bar | Max. 20 bar | Max. 20 bar | Max. 40 bar |

| Thread | G 1½ inch on both sides | G 1½ inch on both sides | G 1½ inch on both sides | G 1½ inch on both sides |

| Wrench width | 55 mm | 55 mm | 55 mm | 17 mm |

|

The FlowJam can be easily installed in the following ways:

|

|