Material flow monitor with blockage detection

Material flow monitoring with Flow/No Flow information plus additional “Detection of blockage” or “Material flow interruption” function (Jam/NoJam)

The FlowJam Plus is a logical development of the established FlowJam sensor which has proved its worth in thousands of applications:

- rapid detection of material movement (Flow/NoFlow)

- additional function “Detection of blockage” or “Material flow interruption”

- Features & Benefits

- Main applications

- Technical Specifications

- Technical Data

- Mounting Installation

- Downloads

- Operates without contact using microwaves

- Particularly reliable device since microwaves can pass through material accumulations

- Measurement can be taken from outside all non-metallic tank walls, housings, hose lines or pipelines

- Can be used even in difficult conditions, in other words high operating temperatures and pressures and in version for Atex zones (with the help of a processadapter)

Chips of wood are transported by two screw conveyors in a biomass plant.

At the transfer point between the screw conveyors, the FlowJam Plus monitors the flow of material.

In the case of a material flow interruption, it is now possible to detect quickly whether there is a problem because the lower screw no longer removes any material or the feed screw no longer supplies material.

Material infeed to a rotary feeder

In a lime plant, lime is conveyed into the inlet of a rotary feeder via a vertical downpipe. At this point, it should be ensured that there is always a sufficient material flow. When the material column reaches the sensor position in the fall line, the FlowJam Plus signals exactly this state. With this information, the material feed can be controlled better.

| Technical Specifications | |

|---|---|

| Material to detect | Dust, powders or granulates |

| Working principle | Microwave |

| Process pressure | Max. 20 bar |

| Process temperature | Up to +220°C |

| Mounting | 1 1/2 ” threat connection |

| Type of Conveying | All |

| Flow rates | No limit |

| Pipe diameter/detection range | Up to 1200 mm |

| ATEX rating | Category 3 |

| Output | Relay |

- For freefall pipeline or a pneumatic transport system

- Operates without contact using microwaves

- Measurement can be taken from outside all non-metallic tank walls, housings, hose lines or pipelines

- Can be used even in difficult conditions, in other words high operating temperatures and pressures and in version for Atex zones (with the help of a processadapter)

| Sensor Technical Data | |

|---|---|

| Housing material | Stainless steel 1.4571 |

| Protective system | IP 65 |

| Process temperature | -20…+80 °C -20…+220 °C (with process adapter) Max. 1000 °C (with ceramic flange) |

| Ambient temperature | -20…+60 °C |

| Working pressure | Max. 1 bar Max. 20 bar (with process adapter) |

| Operating frequency | 24.125 GHz; ± 100 MHz |

| Transmission power | Max. 5 mW |

| Weight | Approx. 560 g |

| Dimensions | Housing: Length 107 mm / Diameter 52 mm Thread: Length 30 mm / Diameter G 1½” |

| Transmitter Technical Data | |

|---|---|

| Power supply | 24 V DC ± 10 % |

| Power consumption | Approx.. 3.5 W |

| Ambient temperature | -20…+60 °C |

| Relay contact | Max. rated load: 250 V AC Max. peak current: 6 A Max. rated load 230 V AC: 250 VA Max. breaking capacity DC1: 3/110/220 V: 3/0.35/0.2 A Min. switching load: 500 mW (10 V/5 mA) |

| Communication | USB |

| Weight | Approx. 172 g |

| Technical Data | ||||

|---|---|---|---|---|

| Pressure adapter | Temperature adapter | Food adapter | High temperature adapter | |

| Material | Stainless steel 1.4571, POM diaphragm |

Stainless steel 1.4571, Tecapeek diaphragm |

Stainless steel 1.4571, Tecapeek GF30 diaphragm/td> |

Steel Ceramic diaphragm |

| Temperature | -20…+80 °C | Max. +220 °C | Max. +220 °C | Max. 1000 °C |

| Pressure | Max. 20 bar | Max. 20 bar | Max. 20 bar | Max. 40 bar |

| Thread | G 1½ inch on both sides | G 1½ inch on both sides | G 1½ inch on both sides | G 1½ inch on both sides |

| Wrench width | 55 mm | 55 mm | 55 mm | 17 mm |

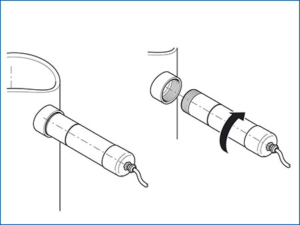

The FlowJam Plus sensor is installed on the line using a G 11/2-inch threaded port.

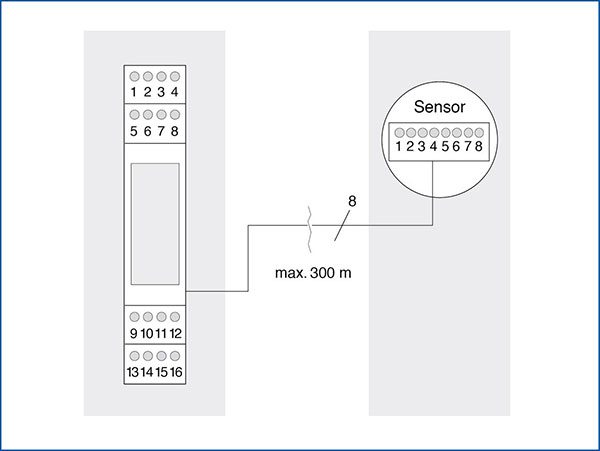

A complete measuring point consists of the following components:

- FlowJamPlus sensor

- DIN rail connector