In-Situ cross duct laser (TDLS) gas analyzer

The In-Situ TDLS gas analyzer has been designed for meeting the requirements of a large range of CEMS and Process applications.

LAS 5000XD uses Tunable Diode Laser Spectroscopy (TDLS) and comes in various models for measuring parameters such as NH3 + H2O, HF, CO + CO2, O2, HCl + H2O, etc.

It combines robustness, fast response time (1 s) and high accuracy measurement in harsh environments (ready for Ex Zone II).

Key operator benefits of LAS 5000XD In-Situ laser gas analyzer:

- No sampling system needed

- No gas temperature influence

- Gas matrix interference free

- Calibration free measurement

Thanks to ClearPath, interference of relative humidity, O2 or CO2 is removed in purging areas.

- KEY FEATURES

- New Embedded ClearPath functionality

- Highly sensitive and selective measurement

- High signal-to-noise ratio

- No measurement drift

- Response time 1 s

- Large dynamic range from ppm to %

- Real-time communication between Transmitter (Tx) and Receiver (Rx)

- Robust, ready for Ex Zone II (certification to come)

- 💡 CLEARPATH

- Interference of relative humidity, O2 or CO2 is removed in purging areas.

- Operator’s benefits:

- No need for N2 or dry air purge

- High accuracy of O2 measurement

- High accuracy of H2O measurement

- High accuracy of CO2 measurement

- CUSTOMER BENEFITS

- Low maintenance and cost of ownership

- No need for N2 or dry air purge: Oil & dust free air instrument is enough

- Process optimization leading to reduction of operating costs

- Ammonia slip control (DeNox)

- Process and combustion control

- HF emission control in aluminum plant

- HCl/SO2 abatement control

- Ethylene cracking furnace control

- HCl level in semiconductor production

- Ammonia concentration control in pet food, fertilizer plants, etc.

| Measurable parameters | |||

|---|---|---|---|

| Pollutant | Range | ||

| NH3 + H2O | 0–10 ppm / 0–5000 ppm + 0–5% / 0–50% | ||

| HF | 0–3 ppm / 0–500 ppm | ||

| CO ppm + H2O | 0-50 ppm / 0-1% + 0-10% / 0-50% | ||

| CO% + H2O | 0-1% / 0-100% + 0-10% / 0-50% | ||

| CO% + CO2 | 0-1% / 0-100% + 0-1% / 0-100% | ||

| CO2 + H2O | 0-1% / 0-100% + 0-10% / 0-50% | ||

| O2 | 0-1%/ 0-100% | ||

| HCl + H2O* | 0-10 ppm / 0-5000 ppm + 0-10% / 0-50% (*gas temperature must be above 150°C). | ||

| Other gases | Available upon request: CH4, H2S, H2, NO… | ||

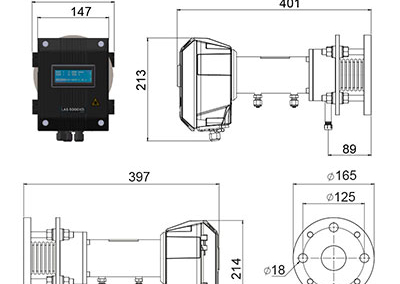

| Technical Specifications | |

|---|---|

| Technology | ADLAS (Advanced Detection Laser Absorption Spectroscopy) • Optimized Opto-Mechanical Design • High Speed Low-Drift Electronics • Powerful Signal Processing and Algorithm • Independent Spectroscopy Technique |

| Lower Detection Limit | < 1% of FS |

| Response Time (0–90%) – Short | 1 s |

| Lack of fit/Linearity | ≤ ±1% |

| Flue Gas Temperature (°C max) NH3 + H2O / HCl + H2O / HF CO + H2O / O2 / CO + CO2 |

+400°C (Depends on the concentration range) +1200°C (Depends on the concentration range) |

| Flue Gas Pressure | 2 bars max (absolute) |

| Display on Tx | 4 x 20 LCD |

| Communication | Modbus RTU (RS485) / Ethernet (RJ45) – Web server |

| Power supply type | + 24 V DC, ripple and noise 50 mV |

| Power consumption | 15 W (warm-up) < 15 W in standard use |

| Recommended T° (ambient) | -20°C to +55°C |

| IP index Tx & Rx enclosures | IP65 |

| Flange specification requirement on stack | DN50 PN16, 2’’ – 150 lbs, Class 150 |

| Flange material | SS 316 L |

| Air consumption (main purge – necessary) |

5-50 L/min (to adjust according to site conditions) (dry and oil free, ISO 8573.1 Class 2-3) |

| Air consumption (secondary purge – recommended) |

2-3 L/min (dry and oil free, ISO 8573.1 Class 2-3) |

| Stack diameter compatibility | From 0.5 to 20 m |

pressure = 1013 mbar / pathlength = 100 cm / ambient temperature = 25 °C

| Options | |

|---|---|

| Junction Box | Analog I/O (2 x 4-20 mA/2 x 4-20 mA) – Digital Output (2 relays) |

| Thermal Shield | Thickness: 20 mm (100°C<Tp<300°C) ; 40 mm (300°C<Tp<600°C) ; 60 mm (Tp above 600°C). |

| Audit Cell | |

| Inline Cell | |

| Alignment Tool | |

| Weather protection covers | |