Moisture measurement with temperature display and material flow monitoring

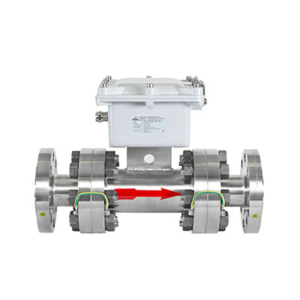

Microwave sensor for continuous moisture measurement in dry bulk solids, with flow detection and process temperature measurement

Sensors for continuous moisture measurement and installation on conveyor belts, screw feeder or hoppers.

Two types of sensor-technology to cover a wide range of applications. Both sensors penetrate the product for most reliable measurements.

Microwave based sensor for high resolution and accuracy.

- highly resistant to abrasion

- integrated temperature reading

- flow detection function

Reliable moisture measurement with high resolution

- Features & Benefits

- Main applications

- Technical Specifications

- Technical Data

- Mounting Installation

- Downloads

- Moisture ranges 0 … 65 % (depending on material)

- Measurement accuracy 0.1 %

- Online moisture measurement

- Instant and accurate process/material temperature measurement from 0 °C to 120 °C

- Flow detection alarm

- Independent of the material colour

- Temperature-resistant up to 120 °C

- Recording of surface moisture and capillary moisture

- ATEX-certified

- Cement

- Chemistry

- Asphalt

- Food

- Glass

- Grain

- Lime

- Minerals

- Steel

- Wood

- Foundry

- Construction materials

- Biomass

- Recycling

- Building materials

- Power plant

| Technical Specifications | |

|---|---|

| Material to measure | Dust, powder, granulates and other bulk solids |

| Place to measure | Screw conveyor, belt conveyor, container, slide, dryer, mixer |

| Working principle | Microwave |

| Moisture range | 0 to 65% (depending on application) |

| Material temperature | Max. 120°C |

| Temperaure measurement | Included |

| Mounting | Flange |

| ATEX rating | Category 1 |

| Output | 4…20mA, Modbus, Profibus |

| Flow detection | Included |

- Moisture ranges: 0 – 65 % (depending on material)

- Measurement accuracy: 0.1 %

- Temperatur resistant: up to 120°

- ATEX – certified

- Materials: alls types of dust, powder, granulates and other bulk solids

- Different mounting positions possible

| Sensor Technical Data | |

|---|---|

| Housing | Stainless steel 1.4571 |

| Sensor surface | Ceramic |

| Ex-protection (optional) | Zone 20 (Dust), Zone 0 (Gas) |

| Protection category | IP 67 according to EN 60529 |

| Material ambient temperature | 0 … +80 °C, optional 120 °C |

| Working pressure | Max. 10 bar |

| Power consumption | 0.6 W |

| Response time | 0.1 sec |

| Weight | Approx. 1000 g |

| Measuring range | 0 … 65 % residual moisture (depending on material) |

| Temperature measurement | 0 … +120 °C ± 0,6 °C (typical) betw. 0 and +120 °C ± 1 °C (Max.) betw. 0 and +70 °C ± 2 °C (Max.) betw. 0 and +120 °C |

| Flow Detection alarm | YES |

| Accuracy | 0.1 % absolutely in the calibrated measuring range |

| Connection cable | shielded cable 4-wired, 0.25 mm2 |

| Transmitter Technical Data | ||||

|---|---|---|---|---|

| Transmitter (DIN Rail) | Transmitter (field housing) | |||

| Power supply | 24 V DC ±10 % | 110 / 230 V AC 50 Hz (optional 24 V DC) |

||

| Power consumption | 20 W / 24 VA | |||

| Protection type | IP 40 to EN 60 529 | IP 65 to EN 60 52 910.91 | ||

| Ambient operating temperature | -10 … +45 °C | |||

| Dimensions (W x H x D) | 23 x 110 x 121 mm | 258 x 237 x 174 mm | ||

| Weight | Approx. 190 g | Approx. 2.5 kg | ||

| DIN rail fastening | DIN 60715 TH35 | / | ||

| Interface | ModBus RTU (RS 485) / USB | RS 485 (ModBus RTU) / USB | ||

| Cable screw connectors | / | 3 x M20 (4.5 – 13 mm Ø) | ||

| Connection terminals cable cross-section |

0.2-2.5 mm2 [AWG 24-14] | |||

| Current output | 2 x 4 … 20 mA (0 … 20 mA), load < 500 Ω |

3 x 4 … 20 mA (0 … 20 mA), load < 500 Ω |

||

| Pulse output | Open Collector – max. 30 V, 20 mA | |||

| Relay contact | Max. rated load: 250 V AC Max. peak current: 6 A Max. rated load 230 V AC: 250 VA Max. breaking capacity DC1: 3/110/220 V: 3/0.35/0.2 A Min. switching load: 500 mW (10 V / 5 mA) |

|||

| Data backup | Flash memory | |||

The M-Sens 3 was developed to offer maximum flexibility during assembly. The following aspects should be taken into account in the positioning of the probe: The measuring field penetrates the densest materials (e. g. sand). With a minimum depth of 120 mm, the probe should always be directed at the material to avoid reflection problems.

Installation situations

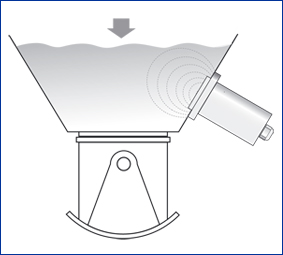

Container

For a simple installation, a standard connection flange is available.

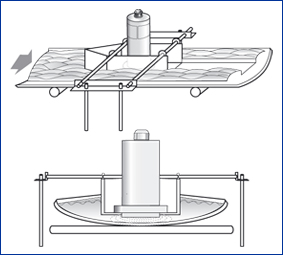

Conveyor belt

Measurement of material moisture on a conveyor belt. A constant material height is generated by attaching a material skimmer. This offers ideal conditions for an online measurement.

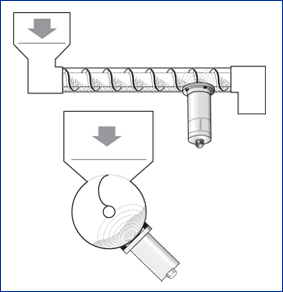

The installation in the lower third of a conveyor screw has the advantage that the material volume that passes over the sensor is almost constant, allowing for an optimal measurement. The movement of the auger flights is hidden.

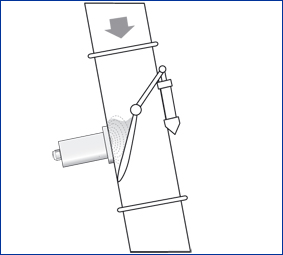

Free fall pipe

To be able to measure in free fall pipes or inclined pipes (chutes) with the M-Sens 3, it is possible to gather material in front of the probe in the short term, for the duration the measurement, with a catching mechanism. After the measurement, the flap will open again and allows the gathered material to continue to drop. The measuring process can be permanently repeated in short or long intervals according to requirements.