Contactless online moisture measurement for solids

ENVEA M-Sens NIR is near-infrared (NIR) spectroscopy technology. Utilizing an intelligent software solution the M-Sens NIR delivers instant, accurate and nondestructive, non-contact moisture measurement.

Near Infrared (NIR) spectroscopy uses light transmission and absorption to measure moisture in a sample material.

M-Sens NIR can be use on various type of material, it is a contactless online moisture measurement.

Because NIR penetrates deeper into bulk material than mid-infrared, it provides better, more reliable measurement on a production line.

Contactless moisture measurement with high accuracy

- Features & Benefits

- Main applications

- Technical Specifications

- Technical Data

- Mounting Installation

- Downloads

- Contactless online measurement

- Non-destructive for all materials

- Rugged design, IP69, ambient temperature up to 80 °C

- Optional: Material temperature measurement

- Short and long-term logs

- Moisture measurement as a percentage

- IoT continuous monitoring of sensor health increases uptime

- Cement

- Chemistry

- Asphalt

- Food

- Glass

- Grain

- Conductive materials

- Lime

- Minerals

- Steel

- Wood

- Foundry

- Construction materials

- Biomass

- Recycling

- Building materials

- Power plant

| TECHNICAL SPECIFICATIONS | |

|---|---|

| Material to measure | Dust, powder, granulates and other bulk solids |

| Place to measure | Screw conveyor, belt conveyor, slide |

| Working principle | NIR spectography |

| Moisture range | 0 to 95% (depending on application) |

| Material temperature | Max. 400°C |

| Temperaure measurement | Optional |

| Mounting | Pole |

| Output | 4…20mA, Modbus, Profinet |

| SENSOR | |

|---|---|

| Moisture range | Min: 0.1 %, Max: 95 % (± 0.1%) |

| Ambient operating temperature | 0 – 80°C |

| Measurement area | 25 mm |

| Product distance | 20.3 – 40.6 cm |

| Sample rate | 60 calculations/second |

| Power | 90 – 260 V AC |

| Outputs | 2 x 4-20 mA, optional discrete I/O |

| Enclosure/Weight | Aluminum / 5.4 kg |

| Certifications | CE, IP69 |

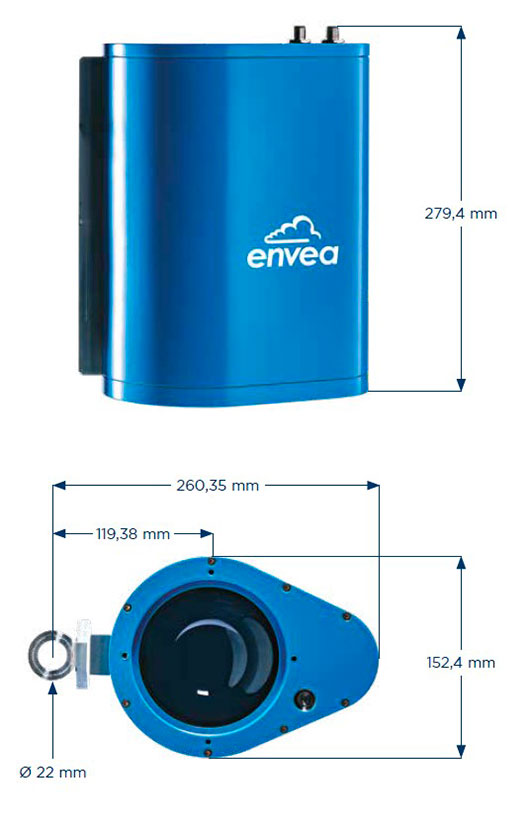

| Dimensions | 279.4 x 260.35 x 152.4 mm (H x L x W) |

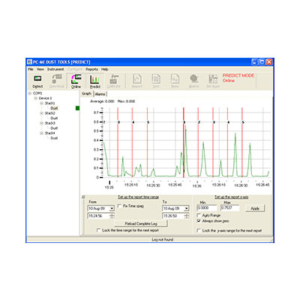

| DATABASE & SOFTWARE INTERFACES | |

|---|---|

| Optional Bus Interfaces |

Ethernet, Ethernet/IP, Profinet, Profibus-DP, Modbus-TCP/IP, Modbus RTU, RS485, DeviceNet |

| Software | Windows-based application, requires Win7 or newer |

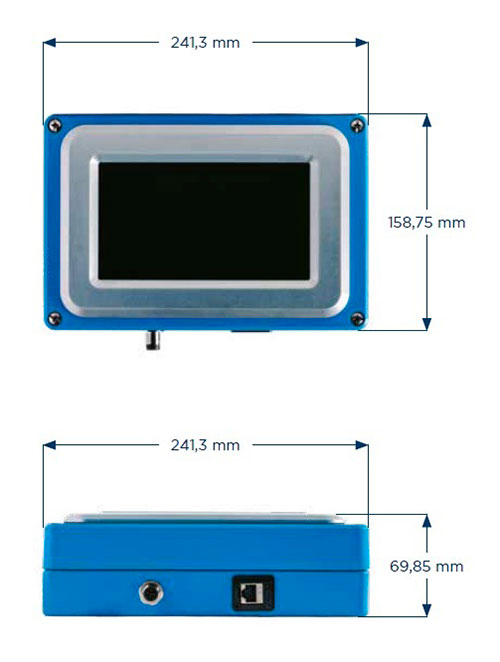

| OPERATOR DISPLAY (OPTIONAL) | |

|---|---|

| Display | 7-inch color capacitive touchscreen |

| Power | 24 VDC |

| Cable | Ethernet |

| Enclosure/Weight | Aluminum / 1.8 kg |

| Ambient operating temperature |

0 to 50˚C |

| Dimensions | 241.3 x 158.75 x 69.85 mm (W x L x H) |

| ACCESSORIES (OPTIONAL) | |

|---|---|

| Temperature Sensor | Measures material in 0 – 400 °C range |

| Opto-Port attachment | This stainless steel attachment allows the sensor to adapt to a variety of situations such as screw conveyors and free fall conveyors. Can be ordered with an air blast system for free falling samples. |

| Dust shield | Ensures the sensor will provide consistentand accurate results by preventing the buildup of dust and grime on the lens |

| OPTO 22 Discrete I/O | Output for alarms (LOP, HH, H, L, LL) |

The sensor shines light onto the surface of the product, and after the light hits the product, the calculations to measure the necessary constituents are done. Filters and cell detectors tailored and optimized for your specific application needs are used to zero in on the exact constituent being measured to provide the best results possible.

The readiness and reliability of this data helps you minimize product loss, eliminate the need for unnecessary downtime, and increases your operation’s efficiency, leading to better margins and increased profits.