In Azomures, we are committed to respecting and promoting the best practices in the field of fertilizers manufacturing, in order to provide the community with optimal conditions for coexistence with an industrial platform. We are aware of our responsibility towards the environment and that is why we have invested significant amounts of money in the refurbishment and modernization of key equipment on the platform. Thus, we managed to reduce the footprint on the environment, under conditions of transparency towards the community. – Environment – AZOMURES“

About the project

The use of QAL1 certified equipment was mandatory as well as regulatory compliance to 96/61/EC (IPPC Directive) – Integrated Pollution Prevention and Control – IPPC Reference Document on Best Available Techniques for Manufacture of Large Volume Inorganic Chemicals – Ammonia, Acids and Fertilisers

Solution

ENVEA and its local distributor RSI Electro have designed a turnkey solution, based on the MIR 9000H – a Heated Multi-Gas NDIR-GFC analyzer perfectly adapted for wet sample gases in corrosive applications such as DeNOx (SCR / SNCR) as well as the MIR 9000e – a new generation of NDIR-GFC Multi-Gas Analyzers offering multi-gas measurement of the N2O (required for this application) but also NOx, SO2, CO, O2, residual H2O, CO2 and CH4.

The solution provided meets and exceeds the requirements, as it include a series of automatic safety and protection features for the pollutants measuring systems. Indeed, during plant start-up, shutdown or maintenance operations, excessive NOx concentrations might occur and can endanger the analytical equipment.

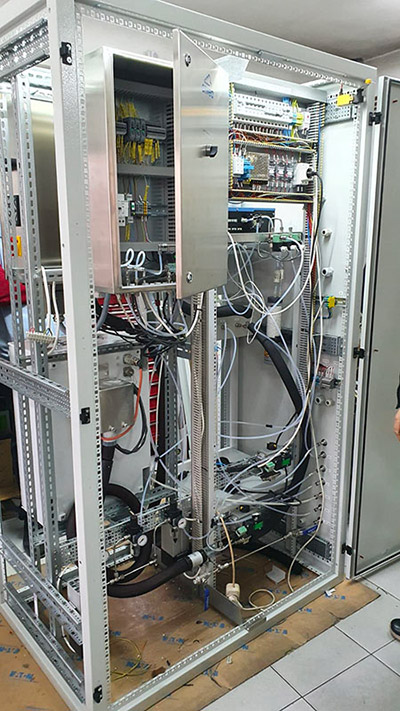

With a long expertise in automation and turnkey design, RSI Electro has taken on the challenge, and has designed an automatic system to protect the NOx & NH3 heated analyzer (MIR 9000H) as well as the N2O analyzer (MIR 9000e) by halting the sampling when the concentration rises above a certain limit and flushing the measuring chamber with instrument air. The system automatically returns to the MEASURE function when the concentration level drops.

Main challenge: to design a reliable automation solution that fully meets the customer specifications and a high-quality turnkey integration.